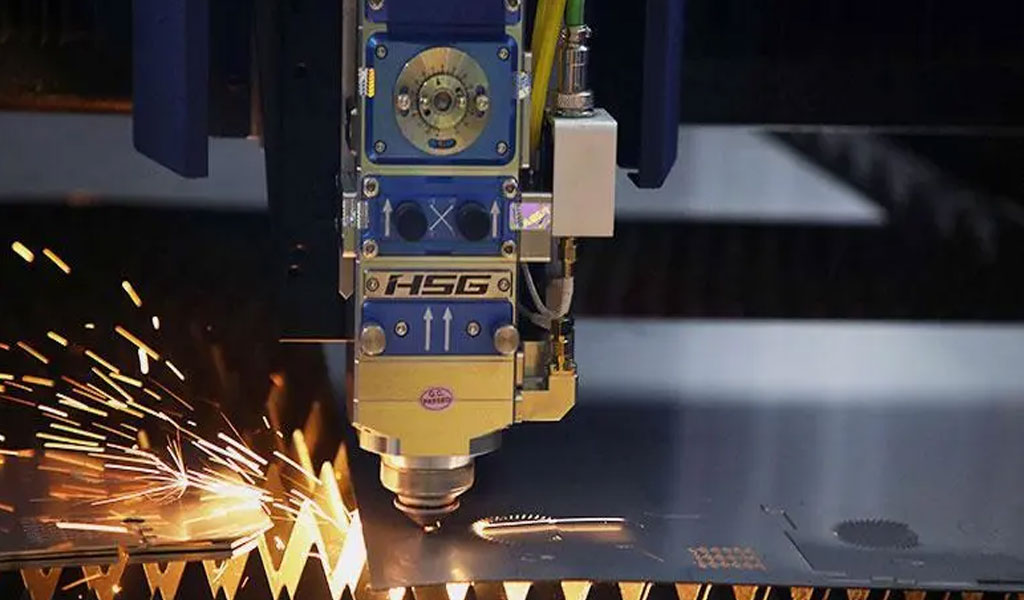

Laser cutting uses high-power density laser as the heat source. Through computer-aided design and computer-aided manufacturing technology, according to the designed cutting trajectory, the surface of the workpiece to be processed is melted, evaporated or decomposed under the irradiation of the laser beam to form a cut. a processing method. Laser cutting is widely used in manufacturing fields such as automobiles, home appliances, and electronic products.

Principle

Laser cutting uses a high-energy-density laser beam to irradiate the cutting area to evaporate or melt the material surface, and at the same time form tiny slits on the material surface to achieve the purpose of cutting. Under the action of laser, due to strong physical and chemical changes on the material surface, the processed material melts, evaporates or decomposes to form incisions.

Laser cutting is a non-contact processing method that does not require tools and molds. There are two types of laser cutting machines: pulse type and continuous type. The pulse type has large output power and fast speed. Continuous laser cutting machines can produce continuously.

Characteristics

Laser cutting equipment is generally divided into three categories: laser cutting machines, laser marking machines and laser engraving machines.

- Laser cutting machine is a processing method that irradiates the workpiece with a high-power density laser beam, causing the surface of the irradiated workpiece to quickly melt or vaporize and vaporize at an extremely high speed, thereby forming a cut.

- Laser marking machine is a method that uses laser beam to locally irradiate materials to melt or evaporate the surface of the material, thereby marking the surface of the material with a long-term mark.

Classification

Laser cutting can be divided into two types according to its cutting method: non-contact and contact.

Non-contact laser cutting machines mainly use laser beams to cut workpieces, rather than generating high temperatures to melt materials like plasma arcs. It is mainly used in the field of plate cutting, such as the cutting of plates, pipes, and profiles; the contact laser cutting machine mainly uses a laser beam to heat the workpiece to partially melt the workpiece, and then blows it away through the nozzle to form a cut.

Application fields

Laser cutting is mainly used for metal plates, including stainless steel, carbon steel, aluminum, copper, titanium and titanium alloys. Among the above-mentioned metal materials, stainless steel and carbon steel are two materials that are currently widely used. Among them, the processing technology of stainless steel is a critical one in the entire laser cutting industry.

With the advancement of technology and the increase of market demand,micro laser cutting technology is developing in the direction of smaller, thinner and more precise. At present, laser cutting has been widely used in automobile manufacturing, home appliance manufacturing, electronic component manufacturing and other fields, and has become one of the important means for the transformation and upgrading of domestic and foreign manufacturing industries.

The Han’s laser coil static cutting system has functions such as one-click automatic uncoiling, automatic leveling, automatic feeding, laser cutting and automatic blanking. It also adopts intermittent static cutting technology, making it easier to operate. The system has a high degree of automation and can greatly improve production efficiency and product quality. At the same time, the system also adopts advanced CNC technology, which is easy to operate and has high reliability. In industrial production, this system is widely used and can be applied to various metal materials of different thicknesses and strengths. It saves production companies a lot of labor and material costs and improves competitiveness and market share.

- Development Trend

- Due to the rapid development of laser processing technology and the continuous improvement of laser cutting processing technology, cutting quality is no longer the single goal of laser cutting. Improving production efficiency, reducing processing costs, further improving micro-laser cutting, and improving laser cutting technology will become important for its development. direction.

- With the continuous advancement of modern manufacturing technology, the functions of laser cutting machines are also constantly improved, and the supporting equipment are also constantly upgraded. People are paying more and more attention to laser cutting processing.

- With the continuous improvement of industrial production requirements, higher requirements have been put forward for the automation and intelligence level of laser cutting machines. Automatic control and intelligent technology will become the new direction of the development of laser cutting machines.

- With the increasing emphasis on green manufacturing and green technology, laser cutting machines are developing in the direction of green and energy saving.

Laser cutting technology is really useful! The application scope of this product is still expanding, and the future development trend is towards high efficiency, precision and adaptability to different materials. It will simply surpass traditional mechanical cutting! Coupled with the continuous emergence of new materials and new processes, the application prospects of laser cutting technology are infinite! Therefore, we need to continue to explore and innovate to improve the accuracy and efficiency of laser cutting technology to a new level! Let’s wait and see!